The horizontal fermenter is a modern industrial device designed for the preparation, maturation, and storage of sourdough in bakery production. Its horizontal cylindrical design allows easy access, efficient mixing, and simple emptying, making it an ideal solution for production plants of all sizes.

Made from high-quality stainless steel (inox), the fermenter ensures the highest hygienic standards, durability, and easy maintenance. The built-in temperature and fermentation time control system creates optimal conditions for the development of natural microflora — lactobacilli and yeasts — which give the dough fullness, aroma, and stability.

Key features:

Volume tailored to bakery needs — from 100 L upwards

Insulated casing with cooling or heating system

Precise process control — manual or automatic

Bottom valve for quick and easy dough discharge

Optional CIP (Clean‑in‑Place) system in agreement with the customer — for automatic cleaning without disassembly

Longer freshness and better bread taste

Faster and more controlled production — ideal for medium and large capacities

Time savings and reduced need for manual labor

The vertical fermenter is an industrial device positioned upright, designed for controlled fermentation and storage of sourdough in bakery production. Due to its vertical cylindrical design, this type of fermenter occupies less floor space, making it a practical solution for bakeries with limited room.

It is made of stainless steel (AISI 304/316), ensuring high hygiene standards, easy maintenance, and durability. It is equipped with a thermal jacket for heating and/or cooling, as well as a system for precise control of temperature and fermentation duration.

Key features:

Space-saving vertical design for production facilities

Volume from 100 L upwards, depending on requirements

Temperature and fermentation time control system

Bottom valve for easy discharge

Option to integrate CIP system for automatic cleaning

Ideal for space-constrained production facilities

Consistent quality and fermentation under controlled conditions

Reduced manual labor and accelerated production process

Easy maintenance and high hygiene levels throughout all phases

CIP (Clean-In-Place) is an automated system for internal cleaning of equipment such as fermenters, tanks, and pipelines, without the need for disassembly or manual cleaning. It is used in the bakery, milling, food, and pharmaceutical industries where hygiene is paramount.

The CIP system aims to provide quick, thorough, and reliable cleaning of production equipment, reduce water and chemical consumption, and increase production efficiency and safety.

Key features:

Automatic cleaning without equipment disassembly

Multiple cycles: rinsing, alkaline cleaning, disinfection, final rinsing

Control unit (manual or automatic – PLC)

Tanks for water, detergents, and disinfectants

Pumps, valves, and sensors for flow, temperature, and conductivity control

Optional return system for solution reuse (recirculation)

Higher hygiene level and production reliability

Shortened cleaning time and reduced costs

Reduced water and chemical consumption

Minimized risk of contamination

Ideal solution for equipment in continuous production (fermenters, mixers, lines)

Industrial silos are used for storage and dosing of raw materials in bulk form such as sugar, salt, flour, starch, mill residues, powdered and granulated additives. They are constructed to provide safe, hygienic, and controlled material logistics in the food and process industry.

Silos can be internal or external, made from stainless steel or aluminum depending on the raw material type and production conditions.

Key features:

Volume according to production needs

Made of AISI 304/316, AlMg

Conical bottom with vibro-fluidization for easy emptying

Integrated sensors for fill and empty levels

Possibility of integration into automatic dosing and transport systems

Dust and pressure control filters

Optional load cells for weight measurement

Safe raw material storage under controlled conditions

Reduces manual labor and improves production efficiency

Enables automatic dosing and precise recipe control

Saves space and simplifies logistics within the production facility

Ability to connect with conveyors, screw conveyors, and weighing systems

Transport pipelines are an essential part of automated production processes, enabling safe, continuous, and hygienic transport of raw materials such as flour, sugar, salt, additives, powdered and granulated components, as well as liquids.

Pipeline systems are individually designed according to production layout, transport volume, and physical properties of the materials.

Key features:

Made of stainless steel (AISI 304/316) or AlMg (for certain food conditions)

Fully enclosed system – prevents contamination and material loss

Smooth internal surfaces – for easy cleaning and minimal residue retention

Manual or automatic cleaning option (CIP)

Various diameters and shapes (straight, angled, Y-branches, etc.)

Customized connections to silos, dosing points, mixers, and packaging

Dosing can be vacuum, blowing, pump-assisted, etc.

Dosing points are key locations within the production process where raw materials such as flour, salt, sugar, water, oils, and additives are automatically or manually dosed into mixers, fermenters, or other process lines. Their primary role is to ensure precision, reliability, and continuity in recipe preparation, resulting in high and consistent product quality.

Depending on production capacity and automation level, dosing points can be manual, semi-automatic, or fully automated, with integration into centralized production management systems (SCADA, PLC, HMI).

Key features:

Precise dosing of raw materials according to predefined recipes

Ability to dose multiple lines or mixers simultaneously

Systems with load cells for accurate quantity control

Control panels with touchscreens (HMI)

Integration with conveyors, silos, and mixers

Automatic recipe recognition and batch dosing records

Optional scanners for operator and raw material identification

Improved product quality and uniformity

Reduced raw material consumption and waste

Reduced human error possibility

Faster batch preparation and better recipe control

Capability to track and archive each dosing event (traceability)

In the modern food, bakery, and processing industries, precise dosing of raw materials is a crucial phase in achieving standardized, high-quality products. We offer a wide range of dosing systems tailored to various raw material types (flour, sugar, additives, powders, liquids) and automation levels.

All systems are designed for easy integration into existing production lines, focusing on accuracy, reliability, and ease of maintenance.

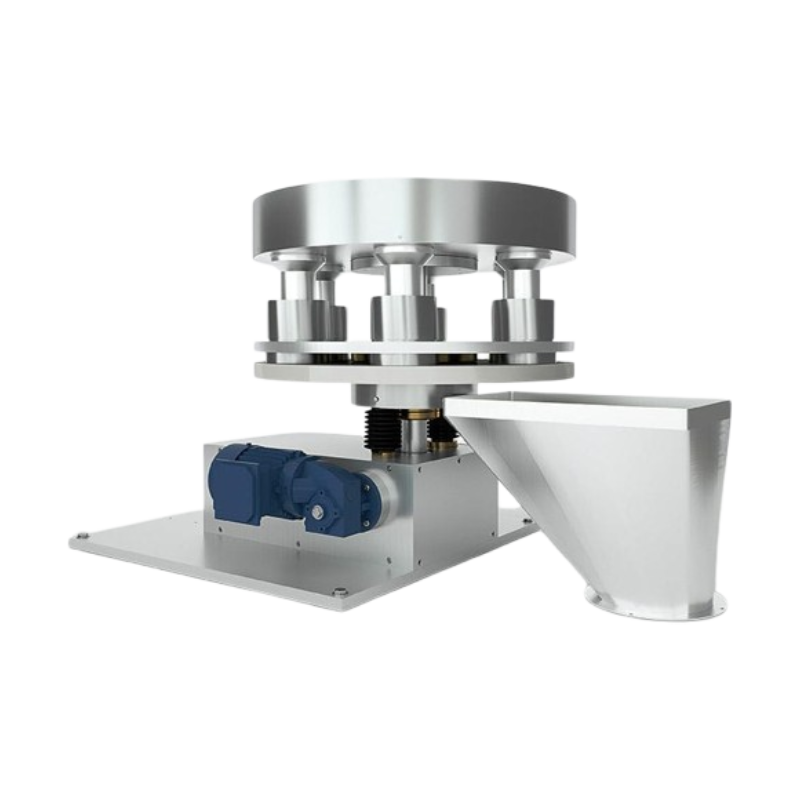

1. Screw dosing systems

Ideal for powdered and granulated materials

Controlled dosing via frequency regulator

Available in coarse and fine dosing versions

Manufactured from stainless steel (AISI 304/316)

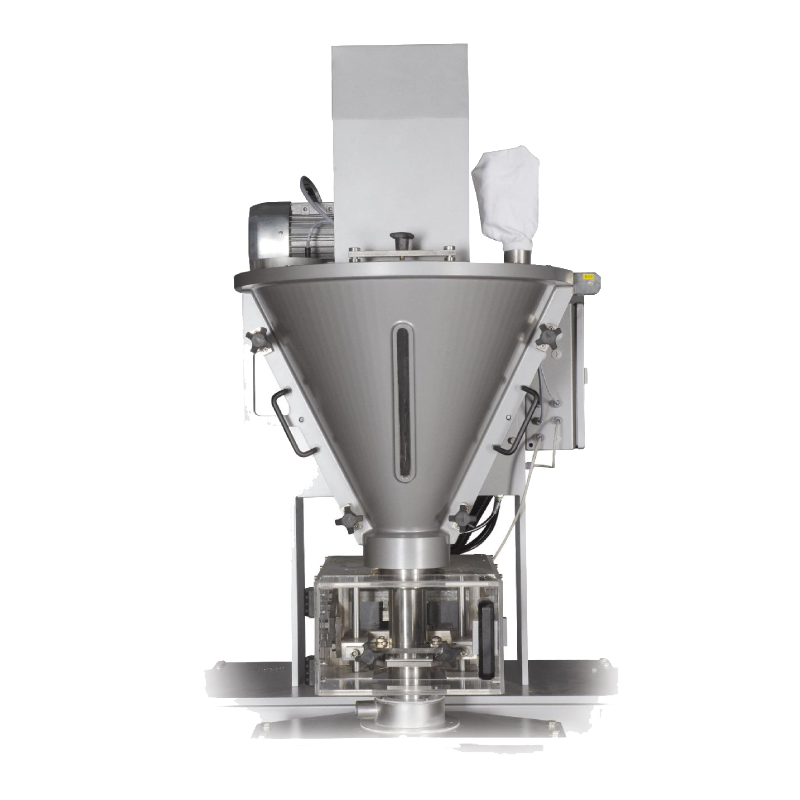

2. Gravimetric dosing systems (by weight)

Scales with load cells for mass measurement

Dosing accuracy ±0.1%

Integration with SCADA/PLC systems

Ideal for automatic dosing of flour, salt, sugar

3. Volumetric dosing systems (by volume)

Dosing based on volume chambers or sensors

Simple solution for liquids, oils, and syrups

Quick installation and low maintenance

4. Manual dosing points

Screen with recipes and operator guidance

Connected to electronic scales

Batch identification and data archiving

5. Fully automated dosing stations

Combination of multiple silos, conveyors, and dosing units

Centralized management system (HMI + PLC)

Simultaneous dosing of multiple components into several mixers

Tech-Construct // All rights reserved // Powered by Creative Smart Solutions 2025.